Article group

Discount store

Scales

Test weights

Hardness accessories

Hardnesstester

Material testing

Laboratory furnaces

Visual inspection

Measuring devices

Industrial marking

Thickness measurement

Metallography

Metrology

Precalibrated

Calipers

Depth measurement

Micrometers

Micrometer head

Mechanical dial gage

Digital dial indicator

Dial gage with sector

Dial Test Indicators

Feeler for dialgage

Dial gauge holder

Saw setting dial gage

Internal measuring

Radius indicator

Measuring marble

Tracing

Gauges

Rulers & squares

Meters

Spirit level

Roughness

Microscopes

Cleaning

Paint

Lightweight comparators

Heavy-duty comparator

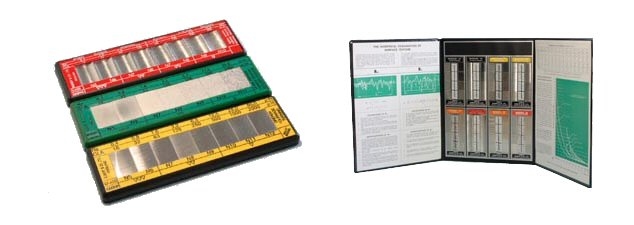

Precision reference specimen

SR2xx

G200

TMR360

Diavite Micro

Diavite Nano

DH-9/App

DH8-Contour

DH8-Tubmaster

Diavite DH-9

Diavite DH10

Taster DIAVITE

DEMOTEC 40

Accessories DIAVITE

Accessories

Certificate

Newsletter

Subscribe to our Newsletter

français

français

Nederlands

Nederlands